Fixed Gas Detection

SP-em

Single Point Environmental Monitor

The SP-em offers a range of microprocessor based detectors for single point gas monitoring. As standard, the monitoring unit comes with an internal sensor, although a range of remote sensors is also available. Typical gases monitored include HCFC, HC and HFC refrigerants, Ammonia, Carbon dioxide, Carbon monoxide, Ethanol, Hydrogen, Natural gases, Propane and Butane.

Make Enquiry Download Product PDFFeatures & Benefits

The SP-em range is a cost effective way of monitoring a single zone for gas leaks. Each SP-em unit can be configured with up to 3 alarm thresholds and features 3 corresponding SPDT relays. High intensity LED indicators provide status indication of leaks in addition to a sensor fault. The standard carbon dioxide monitoring unit will operate down to 0°C, although the low temperature model with internal heater element allows accurate detection down to environments at -30°C

The integral units are available in IP21 and IP54 enclosures (or IP56 enclosure for the CO2 model). Remote sensor options allow the display to be located outside of the monitored space for ease of visibility. Remote sensor options include IP21 & IP54 enclosures (or IP56 enclosure for the CO2 model) together with options for monitoring pressure relief vent lines and ATEX approved housings for potentially explosive and classified zones.

Technical Overview

Operation

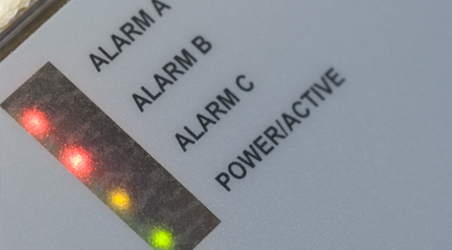

When the unit is first powered up a green LED will flash to indicate the start of the warm-up process. After approximately 4 minutes the green LED will illuminate permanently and the Gas Detector is fully operational. The unit has one yellow and two red warning LED's. The yellow LED indicates a low-level gas leak (above alarm threshold C) whilst the two red LED's indicate gas concentrations above thresholds B and A.

When gas is detected above the respective alarm threshold, the appropriate LED's will light and the corresponding relay contacts change state. If an alarm delay is selected, the respective LED will Flash during the delay period. After the delay period the LED will permanently illuminate and the relay contacts will change state.

Fault Function

In the event of a sensor failure or disconnection of a remote sensor a fault condition will be indicated on the unit. During the first four hours of a fault condition the green LED will be extinguished, remaining LED's will Flash and alarm relay C will change state. After four hours the Red Alarm B LED will be permanently illuminated, the remaining LED's will be extinguished and Alarm C and B relays will change state.

Location

The correct location of the detector is essential and the density of the gas being detected, together with any airflow, must be considered when positioning the sensor. For light gases such as ammonia and hydrogen the sensor should typically be installed at high level, just below the ceiling. Heavy gases such as refrigerants, carbon dioxide & natural gas require sensors to be located at low level with consideration given to air flow. The remote sensor option also allows the display to be located away from the monitored space for ease of viewing.

Calibration

The detectors are supplied factory calibrated for specific gases and are labelled accordingly. Standard alarm settings are based on Health and Safety Exective guidelines for toxic and explosive gases. Custom calibrations are available upon application.

| Properties | |

|---|---|

| Standard Housing | Polycarbonate IP21, IP54 & IP56 |

| Power Supply | 12/24 AC/DC Model or 230 VAC model. |

| Status Indication | Power/Active LED and 3 Alarm LED's. |

| Output Relays SPDT | 3 SPDT relays rated 230V max 5A. |

| Ambient Temperature | -0°C +50°C for Standard CO2 model. -30°C +50°C for low temperature CO2 model. -40°C +50°C for all other models. |

| Dimensions | 60 x 80 x 86 mm |

| Weight | 0.6kg for low temperature CO2 model. |

| Classification | CE |

Accessories

Remote Sensors

A variety of gas sensors housed in an assortment of enclosures can be interfaced to the SP-em. It is essential that the appropriate sensor and housing is selected to suit the gas and environment. A selection of remote sensor housing are detailed, however we recommend discussing your requirements with our technical staff.

-

IP21 Sensor Housing

Model No: EM-RS-IP21

-

IP54 Splash Proof Sensor Housing

Model No: EM-RS-IP54

-

IP56 Sensor Housing For CO2 detection only.

Low Temp (-30°C) Model available.

Model No: EM-RS-IP56-CO2 (-LT)

-

Wall Mounted Room Sensor Housing

Model No: EM-RS-RMF

-

Tubular Sensor Holder (for Plant Monitoring Application)

Model No: EM-RS-TH

-

Relief Line Sensor Holder. Available in Brass or Steel

Model No: (Brass): EM-RS-VB, (Steel): EM-RS-VS

-

Explosive-Rated Sensor Housing (ATEX approved)

Model No: EM-RS-EX

At a Glance

- Microprocessor based monitoring unit.

- Easy to view LED status indicators.

- 12/24 and 230 volt models.

- Three alarm thresholds with corresponding time delays.

- Three alarm relays with SPDT 230 volt rated contacts.

- Manual/auto alarm reset.

- Test programme to verify LED/relay operation.

- IP21/IP54 and IP56 enclosures.

- Extensive range of remote sensor housings to suit all applications.