Fixed Gas Detection

RD-em

Refrigerant Leak detector

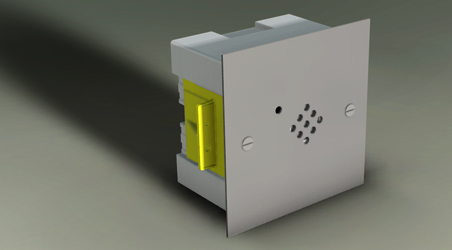

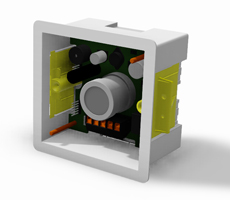

The RD-em provides a discreet and stylish product ideally suited to identification of refrigerant leaks in hotel rooms, offices and residential properties.

Make Enquiry Download Product PDFFeatures & Benefits

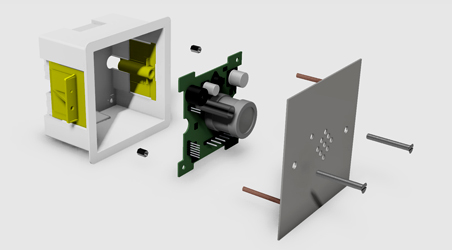

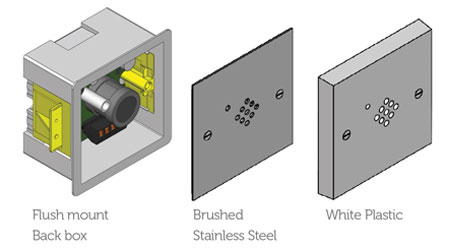

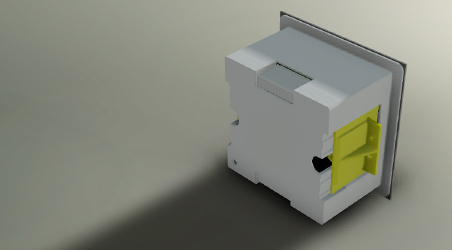

The RD-em sits inside a flush mount electrical back box with a range of cover plates to compliment the electrical switches and sockets fitted in the room. Each microprocessor controlled RD-em is provided fully configured ready to monitor the environment for refrigerant leaks before health and safety limits are exceeded.

A unique feature of the RD-em is its dual alarm operation which enables it to fulfil the requirements of EN378:2008 and the long term exposure limits outlined in the COSSH data sheets for refrigerant 410a, which is typically employed in modern air-conditioning applications. For safety purposes the alarm relay in the RD-em is energised during normal operation and de-energised in the event of a fault or alarm to provide a fail-safe feature.

After power up the green LED will flash during the warm up phase and after approximately 5 minutes will be permanently illuminated to indicate normal operation. In the event of a refrigerant leak the status LED will alternately flash red/amber and the buzzer will sound. In addition the alarm relay will be de-energised to provide remote indication. If the sensor fails the RD-em will also indicate a fault condition. A pre-alarm level is also configured for testing purposes which initiates a flashing status LED, however the relay state remains unchanged. When the refrigerant concentration subsides the alarm on the RD-em will automatically reset.

Contact us for further details.

Technical Overview

Two Alarm Thresholds

The RD-em is configured for two alarm thresholds; a small leak for a long period of time which could contravene the COSSH quoted limits OR a larger leak for a short period of time which could contravene the limits outlined in EN378:2008.

Location

To identify a refrigerant leak and protect personnel it is essential the RD-em is located appropriately. As HFC’s are significantly heavier than air, any leaking refrigerant will accumulate at low level and hence the RD-em needs to be located where it will be most efficient. Detectors should be located in the room installed with the air-conditioning unit, away from windows and doors. In bedrooms an ideal location is beside the bed at low level.

Test Equipment

To test and monitor the performance of the RD-em refrigerant leak detectors, test gas and diagnostic tools are available.

It is recommended that each RD-em is annually tested to verify its performance and operation.

| Technical Information | |

|---|---|

| Cover Plate | White, Brushed Stainless Steel |

| Electrical back box dimensions | Standard profile x 30/40mm deep depending on faceplate |

| Voltage | 12-24V AC/DC |

| Current @ 24V AC | Steady state 100mA, Start-up 250mA |

| Status/Alarm indication | Tri-colour LED |

| Alarm relay | Energised healthy. NO/NC contacts. Rated 24v AC/1amp |

| Buzzer | 85dB, 2300Hz (+/- 300Hz) |

| Certification | CE |

Accessories

IMEC-RAD

Up to 32 RD-em refrigerant leak detectors can be connected to an Imec-RAD panel which will provide low voltage power and visual indication of alarm status. The Imec-RAD offers clear indication via a green/red LED combination of alarm status for each room detector and provides a common alarm relay to activate a buzzer/secondary alarm typically located in a hotel reception, concierge’s office or maintenance location.

A web server in the Imec-RAD also enables the room status to be viewed from a remote PC with a web browser.

At a Glance

- Stylish aesthetic faceplate design

- Fits inside standard electrical back box

- Visual status/alarm indication

- Audible alarm

- Fail safe relay contacts

- Surface finish to match electrical faceplates

- Unique twin alarm feature

- Factory calibrated

- Fulfils requirements of EN378:2008